GARAGE FLOOR EPOXY IN HOUSTON

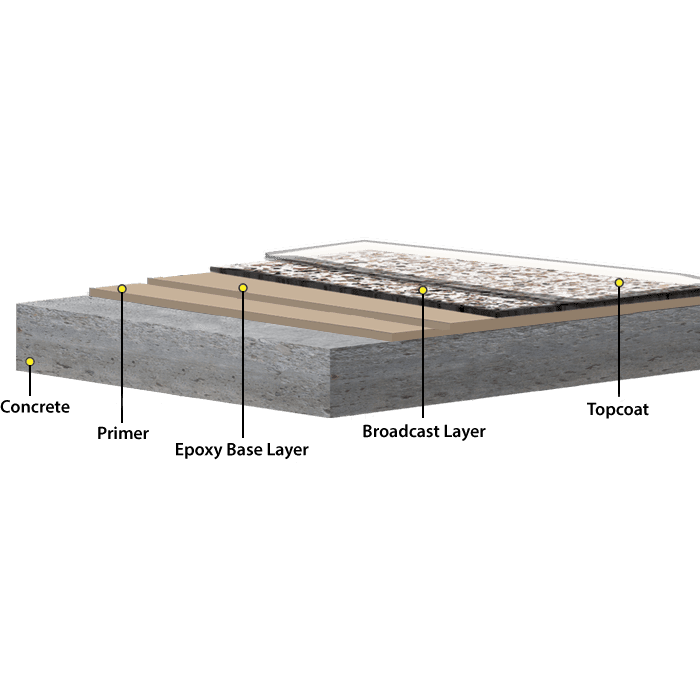

THE PROCESS

The installation process of garage floor epoxy starts with the evaluation of the concrete. First, we need to examine the floor for cracks. Then, we check the floor for moisture. Performing a moisture test is a must. It helps us to avoid the most common problem of epoxy garage floors, like delamination. In short, these steps are essential to evaluate the scope or repair.

Second, we start the preparation step. At this step, we grind concrete to remove the top layer of concrete. Grinding removes dirt and other contaminants to ensure proper adhesion. However, our company would never acid etch the substrate. It’s a common practice. However, the acid etching doesn’t make a surface profile for the perfect adhesion. In addition, rinsing the floor after acid etches entraps moisture. For instance, It can lead to hot tire pickup. While we grind the floor, we start the repairing process. We fill cracks with repairing compounds. After that, we grind the slab to level out all patches.

Thirdly, we apply primer and the broadcast layer. Primer ensures adhesion and seals the pores of the concrete. After the priming step, we proceed with installing the broadcast layer. The body coat is the one that determines the design and overall look.

The last step is applying the topcoat. It creates a hardwearing layer and protects the floor from chemical abuse. For instance, it resists the transmission of fluids, acids, and solvents. In addition, it prevents the epoxy from yellowing caused by sun exposure.

OVERVIEW

Epoxy garage floor has been known as one of the most rigid and durable finishes for garage floors. Its aesthetics and comfort of maintenance make it a good investment for a customer.

It’s getting more and more popular among homeowners. Spills, stains, and cracking on open concrete floor surfaces may affect the look and cause structural issues on the foundation slab. So, epoxy can eliminate these problems.

Unicrete has brought a solution that can turn worn and damaged concrete into a slip-resistant, durable and long-lasting coating. The solution that we install in just one day. Our specialists install cost-effective and attractive coatings suitable for your needs.

EPOXY GARAGE FLOOR BASE COAT

One of the essential layers in epoxy garage floor installation is a base layer. The base coat serves as an intermediate coat that sticks to the concrete slab, holds flakes, and gives a background color. It also takes impact resistance. So, the correct application gives a solid and thick film that covers cracks and other concrete imperfections. Finally, we have 16 colors to complete the custom installation.

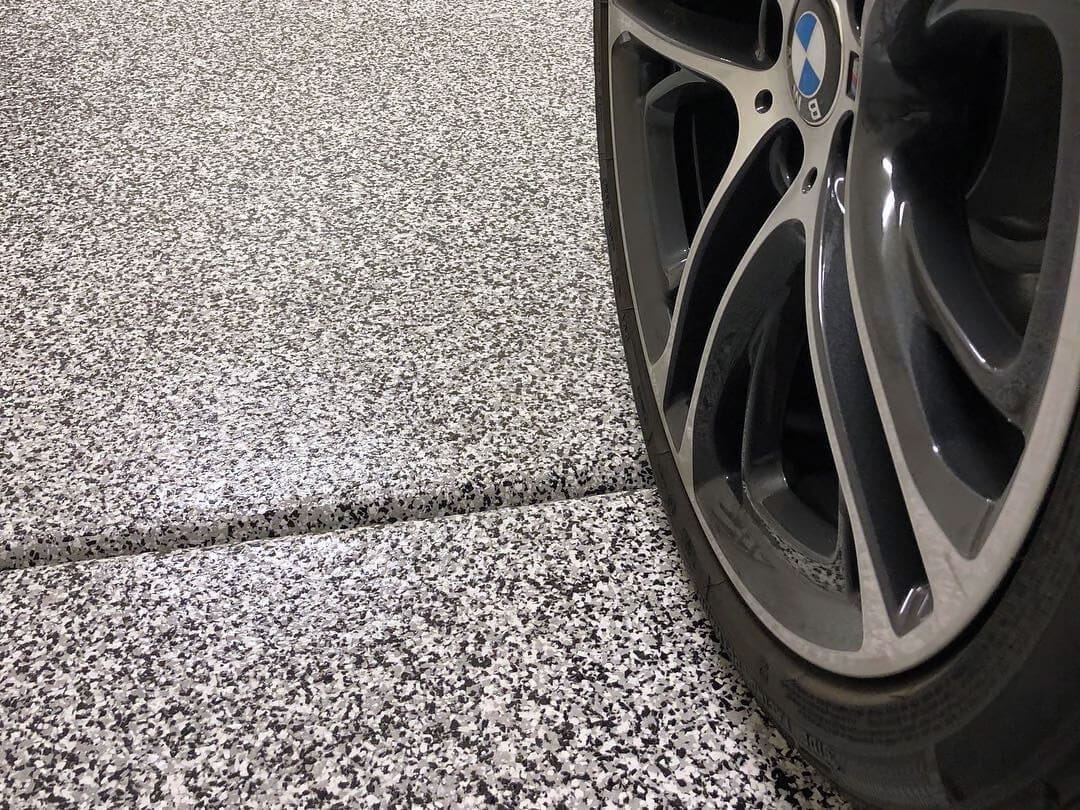

FLAKE BROADCAST

The overall look and texture are not the only duties of a broadcast layer. One of its most significant roles in creating a slip-resistant surface. In other words, the grip made by the broadcast layer significantly decreases a chance of a skid even on wet and greasy epoxy flooring. At the same time, the broadcast layer creates unlimited color options for floor finishes. For instance, most of our customers choose to sprinkle colored vinyl flakes. However, we can leave it plain to create a smooth surface.

FLAKE COVERAGE

The difference between light, medium, or full flake broadcast is the overall look, surface texture, and skid resistance profile. On the one hand, a light broadcast gives you a key to easy maintenance, but on the other hand, a full broadcast provides more slip resistance. Needless to say, these kinds of flake broadcasts have totally different looks. For this reason we have prepared hard samples so you can see the difference.

Also, keep in mind that garage stem walls can be covered with the same type of broadcast to create a uniform appearance.

CUSTOM FLAKE BLENDS

Whenever you look for a unique color blend or a bold solid color layer of colored flakes, be sure we got it. Our variety of colored chips and mixes will turn old and worn concrete into a nice garage epoxy floor finish. Also, for a custom order, we can provide 1/4 inch, 1/8 inch, 1/16 inch, and 1/32 inch chips, including fluorescent and glow-in-the-dark color options.

We can also apply logos, prints, etc. Above all, we can add an antislip additive to increase traction. Anyways, options are limitless. So, schedule an on-site consultation to see samples.

IMPORTANCE OF THE TOPCOAT FOR GARAGE FLOOR EPOXY

The most crucial role in whole epoxy flooring installation is on a top layer. First of all, the top layer must be able to withstand everyday traffic, spills of chemicals, as well as hot tire pickup. Second, choosing the proper one for your floor will help to avoid yellowing, increase abrasion resistance and at the same time make the cleaning process easy and fast.

In addition, customers can also choose between a glossy topcoat, which gives a nice and shiny look, and a satin topcoat, which reduces maintenance routine. Unicrete has epoxy, polyurethane, and polyaspartic topcoats. All of these come in clear or pigmented kits.

Check our weekly updates on Instagram or Completed Projects. Take a look at our ongoing projects. Give us a call. Find us on YouTube. Ask any questions in the comment section. Subscribe to get inspired by our job.

A FREE ON-SITE ESTIMATE!

We provide free on-site consultations to help our customers.

Find what flooring options you can get.

We are proud of our reputation for giving clients proven and long-lasting solutions.